#crown cap sealing machine

Explore tagged Tumblr posts

Text

Get to Know Your Crown Corking Machine: A Comprehensive Guide

If you’re in the business of bottling beverages, then you know just how crucial it is to have a reliable and efficient crown corking machine. This machine is responsible for sealing the bottles and ensuring that your product stays fresh and carbonated for as long as possible. However, with so many different types and models of crown corking machines available, it can be challenging to know which…

View On WordPress

#Automatic Crown Corking Machines#Choosing the Right Crown Corking Machine for Your Business#Crown Corking Machines#How Crown Corking Machines Work#Maintaining Your Crown Corking Machine#Manual Crown Corking Machines#Parts of a Crown Corking Machine#Semi-Automatic Crown Corking Machines#The History of Crown Corking Machines#Troubleshooting Common Issues with Crown Corking Machines#Types of Crown Corking Machines#crown capping machine#capping machine#crown cap sealing machine#beer bottle capper

0 notes

Text

Different Types of Capping Machines for Various Industrial Applications

Capping machines are essential equipment in the packaging industry, ensuring that containers are securely sealed to maintain product integrity and safety. Different types of capping machines cater to diverse industrial applications, each designed to handle specific capping requirements. Below, we explore the most common types of capping machines used across industries.

Cap Pressing Machine A cap pressing machine is designed to securely press-fit caps onto containers without the need for screwing or twisting. This machine is widely used in industries such as beverages, cosmetics, and pharmaceuticals where simple cap designs are common. The machine works efficiently by applying precise downward pressure, ensuring that the cap fits snugly onto the container. Its versatility makes it suitable for various cap sizes and container shapes, and it is often favored for its speed and low maintenance.

Crown Capping Machine The crown capping machine is specifically designed for applying metal crown caps, commonly seen on soda bottles, beer bottles, and other carbonated beverages. It ensures an airtight seal that preserves the product's freshness and carbonation. The machine uses a unique mechanism to crimp the metal cap around the bottle's neck securely. Crown capping machines are durable and capable of high-speed operations, making them ideal for large-scale beverage production lines.

Eye Drop Filling Machine An eye drop filling machine combines filling, capping, and sealing functions for small containers used in pharmaceuticals. This machine precisely fills containers with liquid solutions, ensuring accurate dosage. It then applies and secures dropper caps, ensuring sterility and safety. Designed to handle delicate and small containers, eye drop filling machines are highly specialized and meet stringent pharmaceutical industry standards.

In-Line Capper Machine The in-line capper machine is a versatile and efficient solution for automatic capping in continuous production lines. It is designed to handle screw caps, snap-on caps, and other cap styles. The machine aligns and places caps onto containers moving along a conveyor belt, securing them tightly using torque-controlled mechanisms. This type of machine is widely used in industries such as food, beverages, and household products due to its adaptability and high throughput.

Induction Cap Sealing Machine An induction cap sealing machine uses electromagnetic induction to seal containers with a foil liner. This technology creates a hermetic seal, preventing leakage and ensuring product freshness. It is commonly used in the pharmaceutical, food, and cosmetic industries for tamper-evident packaging. The machine is compatible with various container shapes and sizes, providing an efficient and reliable sealing process that enhances product shelf life.

Measuring/Dosing Cup Placement & Pressing Machine Dosing Cup Placement & Pressing Machine is designed for placing and pressing dosing or measuring cups onto containers, primarily used in pharmaceutical and healthcare products. It automates the placement of cups on bottles, ensuring a secure fit for easy dispensing by the end user. Measuring Cup Placement & Pressing Machine is highly efficient, reducing manual intervention and maintaining hygiene standards. It is ideal for products like syrups, nutritional supplements, and other liquid medications.

Pick and Place Capping Machine A pick and place capping machine offers precision and flexibility in cap placement. This machine picks caps from a feeder and places them accurately onto containers before securing them. It is suitable for irregularly shaped caps or containers, making it an excellent choice for industries such as personal care, cosmetics, and specialty foods. The machine ensures minimal cap damage and provides consistent results even at high speeds.

ROPP Capping Machine (ROPP Cap Sealing Machine) The Roll-On Pilfer-Proof ROPP capping machine is designed for applying aluminum caps onto containers. It is widely used in the pharmaceutical and beverage industries for tamper-evident sealing. ROPP Cap Sealing Machine uses rollers to thread the cap onto the container neck, creating a tight seal without damaging the cap or the container. Its high precision and reliability make it a preferred choice for sealing bottles of liquor, olive oil, and other sensitive products.

Screw Cap Sealing Machine (Chuck Capper) A screw cap sealing machine, also known as a chuck capper, is one of the most common capping solutions for threaded caps. This machine uses a rotating chuck to apply caps with precise torque control, ensuring secure sealing without over-tightening. It is suitable for various container materials, including glass, plastic, and metal. Industries such as food, beverages, and chemicals rely on screw cap sealing machines for their versatility and consistency.

Vial Cap Sealing Machine The vial cap sealing machine is specifically designed for sealing small pharmaceutical vials with aluminum caps. It ensures sterility and safety by applying and crimping caps securely onto the vial neck. This machine is highly precise and adheres to strict industry standards, making it indispensable in pharmaceutical manufacturing. It is capable of handling high volumes while maintaining accuracy, ensuring the integrity of sensitive products such as vaccines and injectable drugs.

Capping machines play a crucial role in modern packaging solutions, offering efficiency, reliability, and precision across various industries. Selecting the right type of capping machine depends on the specific requirements of the product and the production line.

youtube

0 notes

Text

Single Head Bottle Capper Machine

Company Overview: Shiv Shakti Machtech is Manufacturer, Exporter and Supplier of Single Head Bottle Capper Machine. This Machine uses a single head or chuck to apply caps onto bottles or containers with precision and consistency. It operates by placing a bottle under the capping head, where the cap is automatically fed, positioned, and screwed or sealed onto the bottle. These machines typically suit moderate-speed production lines and work best for small to medium-scale packaging operations. The machine is highly adaptable and can handle different types of caps, including screw caps, press-on caps, and crown caps, depending on the specific needs of the product. Its efficiency and precision make it a popular choice in industries requiring fast and reliable capping solutions. Other Names for the Product: Single-Head Screw Capper, Automatic Chuck Capping, Single-Head Bottle Capper, Precision Screw Capper Equipment, Single-Station Capping, Chuck-Style Cap Sealing , Single-Head Cap Tightening Machine, Rotary Screw Capper Machine, Automatic Screw Capping Machine, Single Head Bottle Screw Capper Features: Automated Capping: Reduces manual labor and enhances production efficiency. Versatile Cap Compatibility: Handles screw, flip-top, and crown caps. Precise Torque Control: Ensures secure cap application without damage. Adjustable Settings: Allows customization for cap height, torque, and speed. Compact Design: Space-efficient, ideal for smaller production spaces. Hygienic Operation: Easy to clean, suitable for food, beverage, and pharmaceutical industries. What is a Single Head Bottle Capper Machine? A Single Head Bottle Capper Machine automatically or semi-automatically applies caps to bottles using a single capping head, which applies caps one at a time. How does a Machine work? The machine feeds bottles into the capping station, places a cap, and secures it using a rotating or linear mechanism. It applies torque control to tighten the cap to the correct pressure. What types of caps can a Single Head Bottle Capper handle? A Single Head Bottle Capper can handle a variety of caps, including screw caps, press-on caps, flip-top caps, and spout caps. Shiv Shakti Machtech is a Single Head Bottle Capper Machine and an exporter worldwide, including to Algeria, Angola, Antigua, Barbuda, Argentina, Armenia, Australia, Austria, The Bahamas, Bahrain, Bangladesh, Belarus, Belgium, Belize, Benin, Bhutan, Bolivia, Botswana, Brazil, Brunei, Bulgaria, Burkina Faso, Cambodia, Cameroon, Canada, Central African Republic, Chad, Chile, Colombia, Congo, Democratic Republic of the Congo, Costa Rica, Cuba, Cyprus, Denmark, Dominica, Ecuador, Egypt, Guinea, Ethiopia, Fiji, Finland, France, The Gambia, Georgia, Germany, Ghana, Greece, Guyana, Hungary, Iceland, Indonesia, Iran, Iraq, Ireland, Israel, Italy, Jamaica, Japan, Jordan, Kazakhstan, Kenya, South Korea, North Korea, Kuwait, Kyrgyzstan, Laos, Latvia, Lebanon, Libya, Malawi, Malaysia, Maldives, Mali, Mauritania, Mauritius, Mexico, Moldova, Monaco, Mongolia, Morocco, Mozambique, Myanmar (Burma), Namibia, Nepal, Netherlands, New Zealand, Niger, Nigeria, Norway, Oman, Panama, Peru, Philippines, Poland, Portugal, Qatar, Romania, Russia, Rwanda, Saint Lucia, Saudi Arabia, Senegal, Serbia, Singapore, Slovakia, Somalia, South Africa, Spain, Sri Lanka, Sudan, South Sudan, Sweden, Switzerland, Syria, Taiwan, Tajikistan, Tanzania, Thailand, Togo, Tunisia, Turkey, Uganda, Ukraine, United Arab Emirates (UAE), United Kingdom, United States, Uruguay, Uzbekistan, Vanuatu, Vatican City, Venezuela, Vietnam, Yemen, Zambia, and Zimbabwe. For further details or inquiries, feel free to reach out to us. View Product: Click Here Read the full article

#Ahmedabad#Algeria#Angola#Antigua#Argentina#Armenia#Australia#Austria#Bahrain#Bangladesh#Barbuda#Belarus#Belgium#Belize#Benin#Bhutan#Bolivia#Botswana#Brazil#Brunei#Bulgaria#BurkinaFaso#Cambodia#Cameroon#Canada#CentralAfricanRepublic#Chad#Chile#Colombia#Congo

1 note

·

View note

Text

Beer Events 5.16

Events

Charles Elmer Hires invented root beer (1866)

Bernard Rice patented the Beer Chip (1882)

23rd U.S. Brewers Association convention held (1883)

Fredrick Lauer, founder of U.S. Brewers Association, gave his farewell address (1883)

William Painted patented a Closure for Sealing Bottles (1899)

Schaefer Brewing patented a Crown Cap Selecting Machine (1944)

Labatt introduces Pilsener Lager Beer, later renamed Labatt Blue (1951)

Tennents Brewery became 1st to sell 16 oz. cans in UK (Glasgow, Scotland; 1955)

Ronald Shea patented a Tapping Apparatus for Golden Gate Type Beer Keg Openings (1978)

Supreme Court ruled prohibiting alcohol sales across state lines unconstitutional (2005)

Beer: The Movie documentary premiered (2006)

0 notes

Text

Capping machines are important for sealing containers in the manufacturing industry. Different types include vial cap sealing, crown capping, cap pressing, pick and place and many more.

For more details, visit - https://www.bhagwatipharma.com/capping-machines/

0 notes

Text

Different Types of Packaging Solutions

We are a Packaging Machinery, a leading supplier of packaging machinery solutions in South Africa. Our high-quality, innovative packaging machinery is a bench high machine, designed to allow the straightforward fixing of press-on lids and caps to glass or plastic bottles. It has adjustable top and depth to accommodate a broad range of container heights and cap diameters. We take pleasure to introduce ourselves as one of the leading manufacturer of automatic filling machine, mechanical filling machine, volumetric filling machine, weigh metric filling machine, gravimetric filling machine, capping machine, induction sealing machine - seal machine.

Our products included semi- automatic bench model/ floor model and load cell based filling machine offering versatile filling rang. With our vast experience in this industry, we are able to provide the right solution for diverse customer based, from small startup companies to major national and multi-national companies. We offer all types of ancillary equipment like augers and volumetric fillers, scales, conveyors and cartoning for complete, automated packaging solutions - packaging machines.

It’s our will to enhance your production efficiency, render your higher ROI, and strengthen your brand, with our sustainable filling sealing and packing machines. A over cap machine can change the best way you do things in your factory by easing the capping course of. Why tire and pay dozens of workers when a machine can do all the work with only one operator. Our packaging is a global team of packaging professionals who genuinely care about people. We show our customers that they matter by learning about their challenges and embracing them as our own.

We take a glance at the types of capping machines and when your corporation could require bottle capping machines. Our bottle-filling machines are available in a broad range of types and designs depending on your needs. For instance, wine artisans can choose our vertical crown and cork capping machine while others could as a substitute choose hand-operated corking and capping instruments. Now that you understand the issues to search for when selecting an computerized capping machine, you must do your individual analysis before deciding on that one product. Where possible, you should first compare the manufacturers towards the factors identified above. For more information, please visit our site https://packagingmachinesusa.com/

0 notes

Text

Eversharp Doric Red Shell Gold Emblem Fountain Pen Box Set

Eversharp Doric Fountain Pen Pencil Set - Original red hardcase gift box - Stunning red shell wine red black veined marble - Unique features - 12-sides facet with tapered end - Art-deco gold capband - Double-tick emblem representing Eversharp lifetime warranty Up here is a vintage Eversharp DORIC fountain pen and pencil box-set, second generation, which was manufactured in USA circa 1930s. In 1931 Wahl-Eversharp introduced the fabulous DORIC, which is regarded as the most authentic and recognizable ART DECO vision ever created for a writing instrument. The DORIC's 12-sided faceted design was patented (US Patent No. D81,742) and still turns heads more than 70 years since its introduction. The Wahl-eversharp DORIC for your consideration here is a fine example. It is a complete set, comes with pen and pencil set in a hardcase. There is a sticker original from Jeweler's. Its 12-sided body tapers at both ends, finishing in flattened pyramidal crowns. The 'Double-tick' gold seal emblem represents Eversharp lifetime warranty to the pen. The pen bears a broad art-deco cap band. The pen is fitted with a Eversharp 14ct solid gold nib. The pen bears a lever-filling system; in working condition. Only there are minor wears due to age. This Eversharp Doric fountain pen is very collectible; with numerous stunning features which is rare and highly sought after. Around 1914, Charles R. Keeran invented the basic mechanism for the Eversharp mechanical pencil, thought up the "Eversharp" trademark, and set up a company to make and sell Eversharp pencils. He relocated to Evansville. He soon entered into a business alliance with the Wahl Adding Machine Company in Chicago. Wahl officers obtained a majority share in the Eversharp Pencil Company. In 1940, the Wahl company reorganized under the Eversharp name, which was better know in the marketplace because of the continued success of the Eversharp pencil line. The Eversharp repeater pencil, introduced in 1936, was really driving sales and profits for the company, which had fallen far behind Sheaffer and Parker in total sales revenue. The company was sold to Parker in 1957. You can also view our items on Trumblr. Please also refer to other Eversharp pen in our collection. Read the full article

0 notes

Text

The Semi automatic Single Head ROPP Capping Machine: It’s Just What the Automotive Industry Needs!

As the manufacturing industry advances and grows, so do the technologies and machines used to set up the machines we function on. The semi automatic single head ROPP capping machine is one such technology that is quickly becoming an excellent tool for manufacturers. In this blog post, we’ll search at what a ROPP capping machine is, how it works, and why it’s so important to the manufacturing industry.

What is a Semiautomatic Single Head ROPP Capping Machine?

ROPP stands for “Roll-On Pilfer-Proof” and refers to the type of cap applied to bottles and containers by the machine. The semiautomatic single head ROPP capping machine is specialized machinery that applies these caps to bottles and containers, ensuring that they are tightly and securely sealed. It is called “semiautomatic” because the capping process requires some manual intervention, such as placing the bottle on the machine and starting the capping process.

How Does it Work?

To use the semi automatic single head ROPP capping machine, first place a bottle or container beneath the capping head. The machine then rolls the cap onto the bottle with rollers, creating a tight seal. The capping head can be adjusted to fit various bottle sizes and shapes, making it a versatile tool for the automotive industry.

Why is it Important for the Automotive Industry?

The semi automatic single head ROPP capping machine is an important tool in the automotive industry. To begin, it ensures that bottles and containers are tightly and securely sealed, which is critical for preventing leaks and spills during transportation and storage. Second, because the machine can cap bottles and containers quickly and accurately, it allows for a more efficient and streamlined manufacturing process. Finally, it is a cost-effective solution for automakers because it eliminates the need for manual labor and reduces the risk of errors or accidents.

Conclusion: The semi automatic single head ROPP capping machine is an indispensable tool for the automotive industry, offering a cost-effective, efficient, and dependable solution for capping bottles and containers. Its ability to create tight, secure seals aids in the safe transportation and storage of automotive products while also streamlining the manufacturing process. The semi automatic single head ROPP capping machine will continue to be an important piece of equipment for manufacturers around the world as the automotive industry grows and evolves.

We Siddhivinayak Industries are renowned capping machines Manufacturer in Ahmedabad, Gujarat, INDIA, provide various types of Automatic Screw Capping Machine, Automatic Lug Capping Machine, Semi Automatic Single Head Crown Capping Machine &Automatic ROPP Capping Machine lot.

0 notes

Text

Special features of automatic beer filling machine

The beer automatic filling machine is mainly composed of two parts: a wine filling machine and a capping machine. Wine filling is to transport the beer in the sake tank to the wine storage tank of the wine filling machine, and then the wine filling machine distributes the wine to the wine filling valve, and slowly and steadily put the wine into the wine bottle under equal pressure conditions , and remove the bottleneck air to maintain the quality of beer.

The special points of the automatic beer filling machine are as follows:

1. Two seals, one is the crown cap and the other is the ring-pull cap seal. The rinsing and filling of the two devices can be shared. The two caps are not used at the same time. When using one cap to seal, lift the other. An integral part of a closure will suffice.

2. The lifting and lowering of the filling and capping parts are all electric lifting, which can be realized inside the touch screen, and the adjustment for bottles of different heights is simple and convenient.

3. An anti-slip rod is added to the bottle rinsing part, and the bottom is half-supported when clamping the bottle mouth, so as to ensure that some bottles with less threads or heavy bottles run smoothly.

4. According to the characteristics of beer filling, the filling valve adopts Nanqing special beer valve, and the filling level is accurate.

5. Equipped with a foaming device, before sealing, the air in the bottle is taken out of the bottle to further ensure the purity of the carbon dioxide content and the beer taste.

6. Equipped with a CIP cleaning interface. After the filling of each shift, the customer hangs up the cleaning dummy cup and connects it with a CIP cleaning device to realize deep cleaning of the parts in contact with materials such as filling liquid tanks and filling valves.

0 notes

Text

"What—?" Ben growled, narrow eyes tapering further. Customs ghosts might enjoy flashing before him. Boiling and paring the offerings. A few of those warding sigils flashed, too, in reverse. "Yeah, right."

Pinched the bridge of his nose and drew his cap back down over his brow.

"Just don't want chalk on my lungs."

He had to get out, then. He had to get out under the sky, at least, where the few stars competing with the streetlamps blinked impartially, and the steady trickling pool filters covered up some wet sound louder than the road.

Ben shrugged around the back of the building. The vending machines huddled under the patio awning, humming in sinister unison with the overhead fluorescents. Wetness. Mouth sounds.

He didn't know what he saw at first. Two men in the act, one on all fours, swaying above the other. Then, he registered the ichor, metal, and oil in the air. Then he saw it. All the blood shining black under the motel lights.

Reality folded around him like Saran wrap once he realized he was watching one man, a middle-aged, door-to-door salesman type, in long socks and nothing but, eating his own face. The same man split among two bodies now reconsolidated down to one. The back of one thinning crown, stringy flesh trembling from its chin.

That's what happens if you pay the machine? You feed it money and letter select spits out some backward version of you out from Hell to eat your face like an ape?

Didn't know why he thought a doppelganger would move like a human being.

"Nah."

The man in socks reeled onto his feet and hung over his minced corpse with the deadweight stance of a deactivated animatronic. Moonless sky, a dusty backdrop behind it.

Even with his nails bit into his palms, prompting the tactile sense, Ben knew all the blood drained out of him. That he was feeling nothing. He was vacuum sealed, no more human than a vending machine counterpart. Stiff, abstracted. Only caught Nilza standing beside him now, could barely hear her cussing through the plastic wrap.

"Nilza," Ben hissed. "Enough chalk. Try lead."

He grabbed her arm; there wasn't time to consider either of her comforts, that they'd never touched before now, how easily the kill thought came to him, that he was wrapped in plastic and running out of air. Ben grabbed Nilza's arm and pulled her back inside. Something churning in his gut told him the thing’d already spotted them.

@southern-belle-outcasts

"It's the warding sigils I got from a witch. I don't exactly know what it all means, she wouldn't say and I'm no witch. Just that it would work to keep shit that doesn't belong somewhere out."

She had never really had it fail before, she didn't usually fuck with much that wasn't vamps if she could avoid it. There was tattoos running her body that were covering up scars from when she had run into nastier things. Although, really there was nothing nastier than a vampire in her opinion- just things she didn't have as much know how and experience with, and that was dangerous when it came to the supernatural.

The curiousity of why someone would choose to stay in a place that clearly had a thing or three off about it did make her wonder about his own scar, but that wasn't going to be revisited.

She frowned at the lack of supplies she had. Who walks around with paint sealant anyways? But she did have hair spray, and clear nail polish...she might need more of both after this, if it would even cover the majority of the sigils.

"Unless you're a spook, they're not doing anything to you. And I'm pretty sure ghosts don't eat junk food. Like, 90% anyways."

#southern-belle-outcasts#m. au | excon!ben: the drifter#{enchanted cannibal doppelgangers was my plan for this haunted motel all along...}

3 notes

·

View notes

Text

The Importance of Investing in a High-Quality Crown Capping Machine for Your Bottling Line

Are you in the business of bottling beverages? If so, then you know just how crucial it is to invest in the right equipment to ensure the quality and integrity of your products. One piece of equipment that should not be overlooked is a high-quality crown capping machine. These machines play a vital role in securely sealing your bottles and protecting the contents inside. But why is investing in a…

View On WordPress

0 notes

Text

Beer Events 5.16

Events

Charles Elmer Hires invented root beer (1866)

Bernard Rice patented the Beer Chip (1882)

23rd U.S. Brewers Association convention held (1883)

Fredrick Lauer, founder of U.S. Brewers Association, gave his farewell address (1883)

William Painted patented a Closure for Sealing Bottles (1899)

Schaefer Brewing patented a Crown Cap Selecting Machine (1944)

Labatt introduces Pilsener Lager Beer, later renamed Labatt Blue (1951)

Tennents Brewery became 1st to sell 16 oz. cans in UK (Glasgow, Scotland; 1955)

Ronald Shea patented a Tapping Apparatus for Golden Gate Type Beer Keg Openings (1978)

Supreme Court ruled prohibiting alcohol sales across state lines unconstitutional (2005)

Beer: The Movie documentary premiered (2006)

0 notes

Note

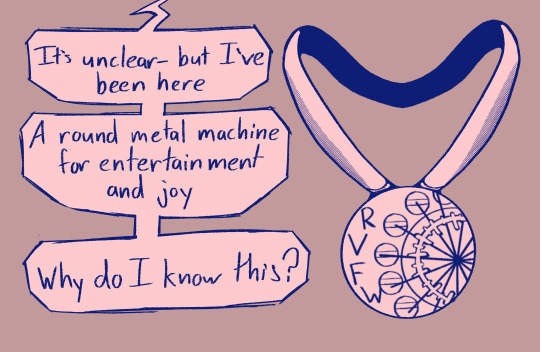

Hmm, Ingo giving Gris a gift or Gris giving Ingo a gift

(So I drew a comic, but then I wrote a blurb. You're getting a two-for-one deal!)

"Here, I made you a gift!"

"For me?" Ingo asked, standing dumbfounded as Gris held the present box up. Their smile widened even more, a dopey giddy grin on their face.

"Yea silly!" They pushed the box further towards him, Ingo happily accepting the gift. The neat box had been wrapped in a bow, Gris hovering over his shoulder, dying to see his partner's reaction. "So I found it in a time distortion, and I think it's from Unova!" They explained, excited to see if Ingo recognized it or not. They had spoken about one another origins, Gris seeing that most of the clues for Ingo pointing towards that region. Gris had gone trinket hunting and had gotten extremely lucky, dodging dangerous pokemon and lightning to scavenge the space altering event. Most of the time, it was for any lost snacks or something useful like tools and devices, but this time, Gris found something rather charming, and maybe, helpful for Ingo. It only took some minor alterations and the right measurements to make it look presentable.

"How wonderful!" Ingo's frown curled into a smile.

"Hurry! Try it on!" Gris hinted at what the item it could be.

He opened the box, Gris must have found it in a distortion as well, the bow being more decorative than the key to keeping the box sealed. Inside he spotted a necklace with a silver medallion sitting on top of some spare soft material. "Ooh! A necklace! I've been meaning to accessorize-" Ingo was very grateful for the gift, cherishing every little thing Gris brought to him but then something on the medallion stopped his speech.

In the fog of his mind, something stirred. Like a murky mirror still reflecting light, the details unclear but it shone brightly.

"Wait- I've seen this before," He realized, the haze lifting more. Taking the medallion out, he examined it. On the face was the depiction of an abstract shape, or perhaps a mechanical machine. Due to the limited space, it was unclear to an unsuspecting eye, but the letters next to it helped. 'R-V-F-W', the letters ringing a bell that he just could tell where it was coming from.

He remembered seeing this shape before, but not in such a small form but to scale, in real life. He remembered it because it had been so grand and astonishing. Breath-taking almost.

"It's unclear- but I've been here." He'd seen this somewhere. "A round metal machine for entertainment and joy," The feelings were coming back to him. He remembered slight fear, overflowing joy and laughter, seeing skylines drift below him. "Why do I know this?" He asked out loud, Gris watching him recover this memory.

He thought some more, clinging to the medallion and piecing the pieces together. Joy, excitement, calmness. Then boredom? He'd seen the machine far too many times it became a passing thing instead of exhilarating.

'They say it's the crown jewel of the city,' Ingo's body froze as he was taken back. This was rare, the times when he did remember a memory so vividly, it was almost like a walking dream, sometimes nightmares.

He was small, a child, a round cap one size to big for him on his head. He was staring up at a poster, the machine displayed on it with grand letters saying 'Fun!' emphasizing it. He couldn't describe the machine as fun anymore, he and someone else had ridden it far too much, the glow having dimmed.

He turned away from the poster, and there it was. The man in white that reflected him, only this time the same height, maybe the same age, or maybe not there at all. The image was still riddled with holes and gaps, again Ingo could not tell if it was truly someone else or himself there.

The other did not speak, but shrugged their shoulders before shaking his head.

'We both agree that ______ is the better place.' The words came out of his mouth, connecting to another memory, this one less clearer. It was a memory of a memory of a place, full of people from all walks of life. He'd seen them arriving and departing, moving in swelled waves and disappearing like tides. It was a marvelous place, or it at least felt like it.

And as suddenly as he'd been reminded of the lost memory, he was pulled back out of it by a voice.

"Ingo! You're crying!" Gris's face had appeared before him, soured and worried. Ingo had dropped the medallion at some point, his hands free to feel his wet face and that he was indeed crying.

He didn't feel sad however, in fact, he felt rather happy. Gris was reaching toward him, to wipe the tears from his tired face, but instead, Ingo moved first. He threw his arms around Gris, holding on as if he would slip away into another vivid dream.

"I'm alright," He told them, feeling a tear trickle down his face. "I remembered something fond just now," He didn't know why he thought of it as fond. It left him wondering who and what the memory was. When was it? And why? Didn't matter, at least not right now. "Thank you love," He thanked Gris for the gift of both a treasure and medallion. Slowly he felt them relax, their racing heat beat returning to normal, returning his embrace and nuzzling into his shoulder.

"You're welcome," Gris said with a shaky voice, never having seen Ingo reaction to positively to a newly found memory before.

#yeah I wrote a small fic and drew a whole comic yw#slightly angsty I guess but it turns sweet#just a little#pokemon#pokemon legends arceus#submas#ingo#pokemon oc#pokemon fanart#pla#pokemon legends ingo#warden ingo#pokémon legends#pokemon fanfiction#ingo fanfic#fanfic#ingo and emmet#emmet#angst#oc x canon#gris#grisingo#text#writing#comic#digital art#answering asks

32 notes

·

View notes

Text

Bottle Cap Machines

These machines work well with bottles of assorted shapes and sizes, providing a managed and uniform cap-sealing process. Inline cap tighteners are recognized for his or her space-efficient design and ease of integration into existing packaging techniques. Various kinds of machines that can seal, rinse, and fill bottles can be found relying on the necessities of the company’s production processes. Many fashions of our bottle capping systems can be used to seal all kinds of bottles or other containers without any modification essential, merely requiring reprogramming on its show. This makes them extremely versatile for companies which ship a broad array of merchandise - coffee packaging machine.Many types of product closures require good, exact positioning and different machines to attain essentially the most appropriate capping. Screw caps and lids are widespread for gentle drinks and beers, and these caps can also be applied using automated machinery or by way of hand. The machine is constructed primarily in stainless steel, with an aluminium alloy superstructure, for use in a clean room - packaging machines. We take a glance at the types of capping machines and when your corporation could require bottle capping machines. Our bottle-filling machines are available in a broad range of types and designs depending on your needs. For instance, wine artisans can choose our vertical crown and cork capping machine while others could as a substitute choose hand-operated corking and capping instruments. Now that you understand the issues to search for when selecting an computerized capping machine, you must do your individual analysis before deciding on that one product. Where possible, you should first compare the manufacturers towards the factors identified above.Bottle cap machines are used to securely seal containers with numerous types of caps or lids. There are a number of forms of bottle sealing machines, together with screw cappers, snap cappers, and crimp cappers, every tailor-made to various kinds of caps and closure mechanisms. Screw cappers are commonly used for plastic or metallic screw-on caps, snap cappers for snap-fit lids, and crimp cappers for sealing aluminium caps on bottles. For more information, please visit our site https://packagingmachinesusa.com/

0 notes

Text

Eversharp Doric Senior Green Shell Gold Emblem Pen Set

Eversharp Doric Senior Fountain Pen Pencil Set - Second generation - Stunning green shell amber semi-transparent veined marble - Unique features - 12-sides facet with tapered end - Art-deco gold capband - Double-tick emblem representing Eversharp lifetime warranty Up here is a vintage Eversharp DORIC fountain pen and pencil set, second generation, which was manufactured in USA circa 1930s. In 1931 Wahl-Eversharp introduced the fabulous DORIC, which is regarded as the most authentic and recognizable ART DECO vision ever created for a writing instrument. The DORIC's 12-sided faceted design was patented (US Patent No. D81,742) and still turns heads more than 70 years since its introduction. The Wahl-eversharp DORIC for your consideration here is a fine example. It is a second generation, SENIOR long bold pen of overall length 5-1/2 inches. Its 12-sided body tapers at both ends, finishing in flattened pyramidal crowns. The 'Double-tick' gold seal emblem represents Eversharp lifetime warranty to the pen. The pen bears a broad art-deco cap band. The pen is fitted with a Eversharp 14ct solid gold nib. The pen bears a plunger-filling system; in working condition. Only there are minor wears due to age. This Eversharp Doric fountain pen set is very collectible; with numerous stunning features which is rare and highly sought after. Around 1914, Charles R. Keeran invented the basic mechanism for the Eversharp mechanical pencil, thought up the "Eversharp" trademark, and set up a company to make and sell Eversharp pencils. He relocated to Evansville. He soon entered into a business alliance with the Wahl Adding Machine Company in Chicago. Wahl officers obtained a majority share in the Eversharp Pencil Company. In 1940, the Wahl company reorganized under the Eversharp name, which was better know in the marketplace because of the continued success of the Eversharp pencil line. The Eversharp repeater pencil, introduced in 1936, was really driving sales and profits for the company, which had fallen far behind Sheaffer and Parker in total sales revenue. The company was sold to Parker in 1957. You can also view our items on Trumblr. Please also refer to other Eversharp pen in our collection. Read the full article

0 notes

Text

Tips for Using a Semi Automatic Single Head ROPP Capping Machine

A semi-automatic single head ROPP capping machine is a great way to speed up your production line. Course, if you are unfamiliar with this type of machine, it can be difficult to use. Here are seven suggestions for making the most of your semi-automatic single head ROPP capping machine:

Understand the ROPP capping process

Automatic ROPP capping Machine is a word for Roll-On Pilfer-Proof. A moving head forms a post all around the neck of the bottle to create a tight seal in this type of capping. Understanding this process is difficult for capping success.

Select the right capping head

Your capping machine should come with a variety of capping heads from which to choose. To ensure the best possible seal, choose the right one for your bottle size and shape.

Set the proper capping torque.

Your capping machine’s torque level must be properly set. If the cap is too tight, it may not seal properly; if it is too loose, it may come off during transportation. The correct torque settings should be found in the manufacturer’s instructions.

Maintain the cleanliness of the machine.

A clean machine is a trustworthy machine. Clean your capping machine on a regular basis to keep it in good working order.

Prepare your operators

Ensure that all operators are properly trained to use the capping machine. Improper machine use can result in product loss, downtime, and even injury.

Keep an eye on the capping process.

Monitor the capping process on a regular basis to ensure consistent torque levels and seal privacy. Make any necessary adjustments to maintain best results.

Maintain the system on a regular basis.

Maintain your capping machine on a regular basis to keep it running smoothly. For recommended maintenance procedures, consult the manufacturer’s instructions.

Finally, a semi-automatic single head ROPP capping machine can be a valuable addition to your manufacturing line. Following these suggestions will ensure that your machine runs smoothly and efficiently, resulting in high-quality seals and increased productivity.

We Siddhivinayak Industries are renowned capping machines Manufacturer in Ahmedabad, Gujarat, INDIA, provide various types of Automatic Screw Capping Machine, Automatic Lug Capping Machine, Semi Automatic Single Head Crown Capping Machine &Automatic ROPP Capping Machine lot.

0 notes